Hey there! If you’ve ever found yourself diving into the world of engineering simulations, then you’ve likely encountered mesh refinement. This nifty technique is like the unsung hero, quietly working behind the scenes to ensure our simulated worlds are both detailed and accurate. Whether you’re an engineering novice or a seasoned pro, understanding mesh refinement can elevate your simulation game. So, let’s jump right in and explore the ins and outs of this fascinating subject!

Read Now : Free 3d Animation Software Download

Understanding Mesh Refinement

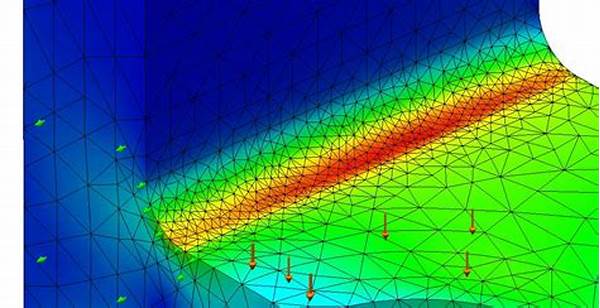

So, what exactly is mesh refinement in engineering simulations? Picture this: you’re working on a digital model that needs to predict how a product behaves under certain conditions. It’s like virtual reality but for engineers! Now, to make these predictions accurate, we need a mesh – a complex web of elements that overlays the model. Mesh refinement comes into play by ensuring that this web is fine-tuned precisely where it’s needed.

The magic of mesh refinement in engineering simulations is that it allows you to concentrate on the details that really matter, like the stress points on a bridge or the heat distribution in a jet engine. By refining the mesh—making it more detailed—you gain insights into small areas without bogging down your entire simulation with unnecessary data everywhere else. It’s like having a magnifying glass exactly where you need it while keeping your broader perspective intact.

But, it’s not just about getting fine details. With mesh refinement in engineering simulations, you also optimize computational resources. This means you make the most of your computer’s processing power without overwhelming it with a gazillion calculations. Balance and precision—the name of the game when it comes to these simulations.

Why Mesh Refinement Matters

1. Precision: Mesh refinement in engineering simulations provides incredible precision. Think of it like adjusting your camera lens to get a sharper image exactly where you need it.

2. Efficiency: It helps in optimizing computational resources which means quicker simulations without compromising accuracy.

3. Focus: Areas that carry significant impact, like stress points on a construction model, receive more attention with mesh refinement.

4. Cost-effective: By refining the mesh only where needed, it reduces unnecessary computational expenses.

5. Enhanced Results: Ultimately, mesh refinement in engineering simulations enables engineers to achieve better, more reliable results.

The Process of Mesh Refinement

Delving deeper, let’s chat about the process behind mesh refinement in engineering simulations. At its core, the procedure involves identifying parts of the model that require more detailed analysis. The technique is comparable to zooming in on a high-definition photo to reveal finer details without losing the big picture.

The actual process often begins with a coarse mesh which is evaluated to identify areas where the results might not be accurate enough. Engineers analyze these areas, making judgments about where refinement is needed. Adding more nodes and elements ensure that the simulations account for intricate behaviors, like the way heat moves through a material or how pressure impacts a surface. Mesh refinement means tweaking the mesh’s density, allowing simulations to handle complex physical phenomena seamlessly. As a result, you end up with simulations that are not only faster but also incredibly accurate.

Benefits of Mesh Refinement

1. Resource Allocation: By applying mesh refinement in engineering simulations, you allocate resources more efficiently, focusing computational power where it really counts.

2. Reduced Errors: The improved precision obtained through mesh refinement translates into reduced errors in the simulation outcomes.

3. Scalability: Mesh refinement allows simulations to be scalable, adapting to small or large scale systems effectively.

Read Now : Rigid-soft Composite Material Properties

4. Speed: Overall simulation times decrease, which is a big win in iterative design processes.

5. Adaptability: Models can be tweaked easily to test different scenarios, thanks to scalable mesh refinement.

6. Real-World Accuracy: By zeroing in on critical areas, mesh refinement helps mimic real-world events more realistically.

7. Predictive Power: Accurate simulations mean better predictive power for future performance assessments.

8. Design Optimization: Through precision, designs can be optimized and refined substantially.

9. Risk Minimization: Engineers can identify potential issues ahead of time, minimizing risk in real-world applications.

10. User Confidence: Knowing that the simulation results are reliable builds trust and confidence in the engineering methods employed.

Challenges in Mesh Refinement

While mesh refinement in engineering simulations is a powerful tool, it does not come without its challenges. For one, the initial setup and determination of where exactly to apply refinement demand expertise and can be time-consuming. There’s always a balance to maintain between refinement and computational overhead; push too far, and you might end up overloading your computer systems.

Choosing the right mesh refinement strategy might involve some trial and error before you get it just right. Additionally, understanding the underlying physics of the problem ensures that the refinement meanings make sense, and poor application can lead the simulations astray. Despite these challenges, the benefits often outweigh the costs as mesh refinement paves the way to more insightful simulations.

Conclusion to Mesh Refinement

In summary, mesh refinement in engineering simulations serves as a bridge between raw computational power and nuanced, impactful results. It allows engineers to create highly detailed simulations by focusing on areas that demand extra attention while maintaining so much-needed efficiency. Through optimizing resource usage and reducing computational burden, mesh refinement is integral to diving deeper into detailed, reliable simulations.

It becomes clear that mesh refinement is here to stay as a cornerstone of advanced engineering simulations. With the ability to yield profound insights and optimize designs, its value in solving real-world engineering problems cannot be overstated. Whether you’re tackling stress analysis, thermal studies, or fluid dynamics, mastery over mesh refinement techniques will empower you to elevate your simulation endeavors to new heights.