Hey there, awesome people! Today, we’re diving into something pretty intriguing but surprisingly chill at the same time – acoustic emission depth assessment. If you’ve stumbled upon this term and wondered, “What in the world is that?” you’re in the right place. It’s all about using sound waves to tell us what’s happening deep inside materials, which is not only pretty cool but also super useful in a bunch of fields. So, grab your favorite drink, get comfy, and let’s explore this fascinating topic together.

Read Now : Downloadable Game Art Backgrounds Free

Understanding Acoustic Emission Depth Assessment

Alright, first things first: let’s break down what acoustic emission depth assessment actually is. Imagine you could hear a material speak, interpreting its moans and groans to figure out what’s going on beneath its surface. That’s kind of the magic we’re dealing with here. This assessment technique uses the natural sound emissions from materials when they’re stressed to evaluate the depth and significance of any internal flaws or changes. Think of it as listening to the whispers of hidden cracks, telling tales of the material’s integrity. By analyzing these acoustic signals, scientists and engineers can determine how deep an issue goes and how serious it might be. The best part? It’s a non-destructive method, meaning no need to ruin perfectly good materials during testing.

How Acoustic Emission Depth Assessment Works

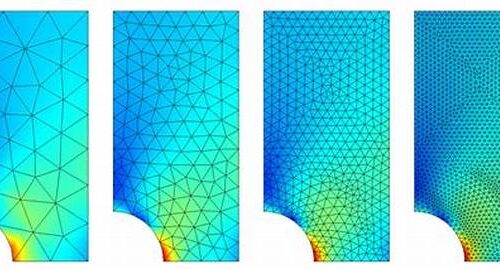

1. Sound Wave Magic: Acoustic emission depth assessment uses the sound waves generated by the materials. As flaws develop or grow, they release high-frequency sounds that can be detected and analyzed.

2. Listening Devices: Special sensors, or ‘ears’, are attached to the material to pick up the sound emissions, like having a super-sensitive microphone.

3. Signal Interpretation: These signals are then analyzed to determine the depth and severity of the flaw, akin to a doctor interpreting an x-ray.

4. Data Visualization: Advanced tech helps visualize the flaws, offering a detailed picture of what’s happening beneath the surface without breaking a sweat.

5. Non-Invasive: Acoustic emission depth assessment ensures materials aren’t damaged during testing, preserving their integrity while assessing their condition.

The Importance of Acoustic Emission Depth Assessment

Now, you might wonder why all the fuss around acoustic emission depth assessment. Well, think about industries like construction, aerospace, and even healthcare, where the structural integrity of materials is crucial. This method offers a non-invasive way to ensure safety and durability. By catching potential issues before they become big problems, engineers can save costs and prevent disasters. It’s like having a guardian angel keeping an ear out for any structural mischief. Moreover, using sound waves as a diagnostic tool presents a sustainable approach, reducing the need for wasteful testing methods. Plus, the geeky side of us just loves the idea of materials having their own secret language.

Benefits of Acoustic Emission Depth Assessment

1. Cost-Effective: Acoustic emission depth assessment provides a cost-efficient way to check materials for flaws without causing damage.

2. Early Detection: It helps in spotting potential structural issues early, which can be crucial in preventing bigger, more costly problems down the line.

3. Versatile Application: Whether it’s assessing the wings of a plane or the beams of a bridge, this technique is incredibly versatile.

4. Environmental Impact: Since it’s non-destructive, there’s less material waste and fewer resources needed for rigorous testing procedures.

Read Now : Tips For Platformer Animation Techniques

5. Real-Time Monitoring: Acoustic emission depth assessment allows for real-time monitoring of material conditions, offering immediate insight.

6. High Accuracy: The precision of this method ensures that even minute flaws are detected and assessed accurately.

7. Remote Capability: In some configurations, it can be used remotely, making it ideal for hazardous environments.

8. Continuous Improvement: As technology evolves, so does the accuracy and application range of this method.

9. User-Friendly: With the right technology, it’s not only experts who can utilize this tool—its usability is improving continually.

10. Peace of Mind: Knowing that there’s a reliable method to check structural integrity offers peace of mind in both personal and industrial contexts.

The Future of Acoustic Emission Depth Assessment

Peeking into the future, acoustic emission depth assessment is definitely on the rise. As technology advances, we’re seeing more refined sensors and smarter algorithms making their way into this field. These improvements mean even greater accuracy and broader applications. Imagine being able to assess everything from ancient buildings to futuristic spacecraft with just a few sensors and a bit of software magic. It’s a bit like sci-fi, right? The potential is massive, especially as industries continue to prioritize sustainability and longevity. By embracing these methods, we’re not only boosting safety and saving resources, but also paving the way for more resilient, sustainable industrial practices. The journey of acoustic emission depth assessment is just getting started, with lots of exciting developments on the horizon.

A Chat about Acoustic Emission Depth Assessment

So, there you have it – acoustic emission depth assessment in a not-so-nutshell. Whether you’re a seasoned engineer or just someone curious about the secret sounds of materials, this technique offers a fascinating glimpse into the invisible world of structural integrity. It’s amazing how much we can learn from listening to what materials have to say. As we continue to refine these methods, the potential for safer and more efficient structures only grows. Until next time, keep your ears open – who knows what whispers you might catch in the world around you?