Hey there, curious minds! Ever wondered what happens when materials bend, twist, or break under pressure? Welcome to the fascinating world of material deformation mechanics. It’s like the under-the-hood science of why buildings sway in the wind, why bridges can withstand massive weights, and even why your favorite superhero’s shield can take a hit! While it might sound all technical and sciency, I promise it’s more relatable than you think. Let’s dive right in and unravel what makes this topic oh-so-interesting!

Read Now : Optimizing Customer Experience Stages

Exploring Material Deformation Mechanics

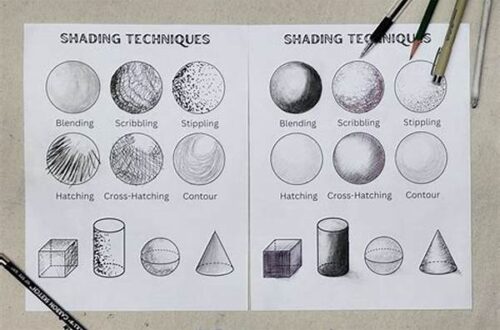

So, what’s the big deal with material deformation mechanics anyway? Picture this: you’ve got a rubber band in one hand and a steel rod in the other. You stretch the rubber; it snaps back in place. You try bending the steel—good luck with that! This is the heart of deformation mechanics, which looks at how materials respond differently to forces. From elasticity to plasticity, these concepts help us understand why certain materials behave the way they do. It’s like each material’s little personality coming to life under stress. Whether you’re an engineer, an artist, or just someone who wonders why stuff breaks, this science has a story to tell. Yep, even metals and tissues have their breaking points, and that’s where the magic of mechanics steps in to save the day and help us predict failures before they happen.

Key Aspects of Material Deformation Mechanics

1. Elasticity Vs. Plasticity: Elasticity is the material’s ability to return to its original shape, while plasticity refers to how it deforms permanently. In material deformation mechanics, this helps us know what materials to use for different needs.

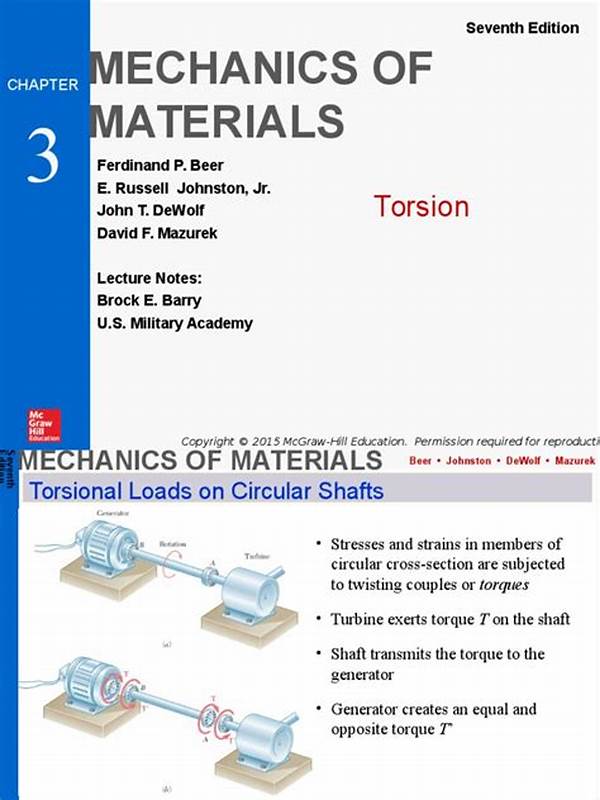

2. Stress and Strain: These two are like besties in material deformation mechanics. Stress is the force applied, while strain is the result of that force. Together, they determine how a material deforms.

3. Yield Strength: This is the maximum stress a material can withstand before it begins to deform plastically. Knowing this helps engineers design structures that won’t fail catastrophically when the limits are tested in material deformation mechanics.

4. Toughness: A material’s ability to absorb energy before fracturing. Toughness is integral in material deformation mechanics, particularly in materials that must withstand impact without cracking.

5. Failure Analysis: Not just about something breaking but understanding how and why it fails. Material deformation mechanics dives deep into these investigations to prevent future mishaps.

The Science Behind Deformation

Okay, let’s break it down a bit more. The study of material deformation mechanics is essentially about understanding what materials do when forces act upon them. Imagine a gymnast bending and twisting gracefully. There’s an inherent elasticity and plasticity in her movements—this is exactly what we explore with materials when we study how they deform. The ability of a material to absorb forces, distribute them, and eventually return to its original shape (or not) defines their practical uses. Engineers and scientists use this knowledge to ensure safety and functionality in everything from buildings to everyday objects.

In a deeper dive into material deformation mechanics, we find that it’s not just about metals and large structures. Think about your everyday items—your smartphone case, the fabric in your clothes, the plastic of a water bottle. All of these, at some point, rely on principles of deformation mechanics to maintain integrity while being functional. How cool is that? Each material is like a carefully crafted dance to ensure everything from breakable glass to resilient metals perform just right under stress.

Practical Applications of Material Deformation Mechanics

Understanding material deformation mechanics isn’t just academic; it finds application in real-world scenarios almost everywhere! From building skyscrapers that can withstand earthquakes to creating flexible electronics, this science is part of the magic formula.

1. Architecture and Construction: Ensuring structural integrity under various stresses requires deep knowledge of material deformation mechanics. It’s how architects design buildings that can withstand both time and tremors.

2. Automotive Industry: Ever wondered why cars are so safe? Yep, part of it comes down to utilizing material deformation mechanics to design crumple zones and safer vehicle frames.

3. Aerospace Engineering: From aircraft fuselages to spacecraft, understanding how materials deform is crucial. This ensures safety and performance at high speeds and stresses.

4. Biomechanics: Here, material deformation mechanics helps us understand how biological tissues can withstand pressures, leading to advancements in medical devices and prosthetics.

5. Manufacturing: The production of products using various materials means material deformation mechanics is essential to ensure everything from flexibility to durability.

Read Now : Digital Twin Predictive Analytics

6. Energy Industry: Whether in pipelines or solar panels, understanding deformation helps in designing efficient and long-lasting solutions for energy needs.

7. Textile Industry: Some fabrics need stretch, some need to hold form. Insights from material deformation mechanics help in creating everything from stretchy yoga pants to durable military uniforms.

8. Electronics: Flexible circuits and screens rely on understanding material deformation mechanics to ensure functionality without breaking.

9. Civil Engineering: Bridges and tunnels use these principles to withstand both natural and man-made forces, ensuring safety and longevity.

10. Sports Equipment: From golf clubs to running shoes, performance materials rely on material deformation mechanics to enhance durability and user experience.

Challenges and Innovations in Material Deformation Mechanics

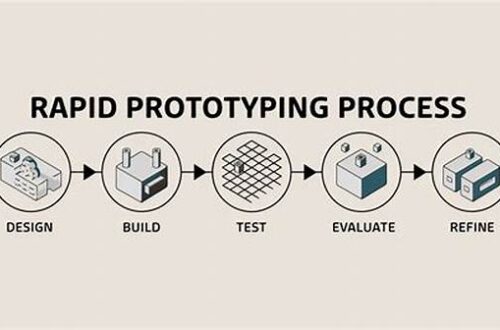

As we continue our journey into the dimensions of material deformation mechanics, it’s clear that this field isn’t just about preventing things from breaking. It’s about discovering new materials and pushing the boundaries of what’s possible. The field is evolving rapidly with new technologies like AI and machine learning helping us predict material behavior before even creating prototypes. This predictive capability is allowing for more robust designs and safer structures. What once took years of testing can now be modeled in months or even weeks!

Material innovations like smart materials that change properties under stress are revolutionizing industries, from creating adaptive sports gear to protective materials in cars and electronics. The focus on sustainability also plays a pivotal role in shaping the future of material deformation mechanics. Researchers are constantly seeking materials that provide optimal performance but with a reduced environmental footprint. Who knows, maybe the next big thing is just around the corner, transforming how we think about everything from the clothes we wear to the cars we drive!

Future of Material Deformation Mechanics

As technology advances, so does the field of material deformation mechanics. The future looks bright with developments in nanoscale materials, where properties at tiny scales open doors to innovations we’ve only dreamed about. With the blend of multidisciplinary fields—physics, engineering, chemistry—coming together, the potential for breakthroughs is immense.

Imagine a future where buildings adapt to changes in environment, self-healing materials prolong life and durability, and super-light, ultra-strong materials redefine transportation. The fusion of AI in this field isn’t just a possibility but a rapidly unfolding reality where it forecasts stresses and strains with precision, redefining design and safety standards across industries. The journey into material deformation mechanics is not just an academic curiosity but a critical path into the sustainable, safe, and resilient future we envision.

Wrapping it Up

Alright, folks, let’s wrap up our little journey into material deformation mechanics. We’ve covered a lot of ground, from how materials resist forces to safely allowing buildings and vehicles to bend, flex, and stand tall. This field is not just about avoiding breaks and bends but about creating the amazing feats of engineering that pepper our world. Whether it’s the technology we use daily or the structures we marvel at, understanding the mechanics behind it plays a critical role.

While the terms can get a bit technical, the beauty lies in seeing how science meets creativity to solve real-world problems. Remember, every bridge that stands strong in a storm, every skyscraper that dances with the wind, and every piece of technology that withstands daily wear and tear owes a bit of its resilience to material deformation mechanics. It’s a field that blends intrigue, innovation, and practicality, continually shaping the world around us. And who knows, with a little imagination and continued research, the future possibilities are boundless!