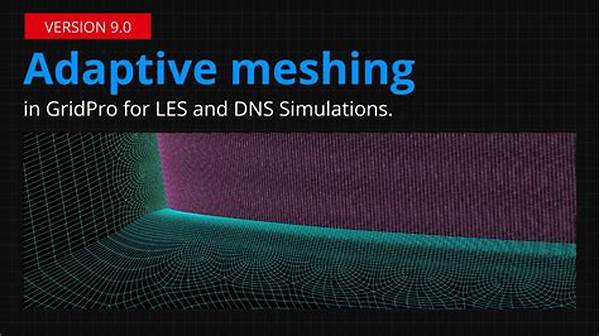

Hey there, fellow simulation enthusiasts! Have you ever wondered how some simulations can be incredibly detailed and precise without burning up all your computer’s resources? The secret lies in a little something called “adaptive meshing.” If you’re not familiar with this term, don’t worry—you’re in the right place! Join me as I delve into the world of adaptive meshing in simulations, exploring what it is and why it’s a game-changer.

Read Now : Integrating Ads Seamlessly In Games

What is Adaptive Meshing in Simulations?

Imagine you’re working on a simulation of a complex fluid flow around a sleek racing car. You want the simulation to capture every little swirl and eddy in the air current—without crashing your computer. This is where adaptive meshing in simulations comes in handy. Essentially, it’s a method that adjusts the mesh resolution dynamically while the simulation is running. Picture a grid overlaying your model; adaptive meshing allows that grid to be finer in areas with lots of activity and coarser where things are relatively calm. It’s like zooming in for detail only when required, making simulations way more efficient. By optimizing the computation power, adaptive meshing in simulations makes it possible to run high-resolution models on standard hardware, and that’s pretty awesome.

Why is Adaptive Meshing Awesome?

1. Precision in Details

Adaptive meshing in simulations allows for crisp details in complex areas while keeping it light elsewhere.

2. Efficient Resource Use

It helps in conserving computational resources, focusing power where it truly matters.

3. Faster Simulations

You don’t need to wait forever—adaptive meshing in simulations speeds up the process significantly.

4. Scalability

As your simulation grows, adaptive meshing scales with it without breaking a sweat.

Read Now : Intuitive Design Interface Strategies

5. User-Friendly

It usually doesn’t require expert-level tweaks, allowing more people to enjoy its benefits.

Benefits of Implementing Adaptive Meshing

Okay, so you’ve got the basic idea, but why should you consider using adaptive meshing in simulations for your projects? Well, imagine you’re designing a new wind turbine. You need precise simulations to ensure efficiency and safety. Regular mesh methods might require you to use a supercomputer, but with adaptive meshing, you can run these simulations on typical workstations. This not only saves money but also opens the doors for smaller labs and independent researchers to innovate without worrying about access to high-end computing resources. Moreover, adaptive meshing in simulations leads to faster computation times. Projects that used to take weeks can now be accomplished in days or even hours. So, whether you’re in academia or industry, adaptive meshing isn’t just a nice-to-have—it’s essential for staying competitive.

How Adaptive Meshing Transforms Industries

The beauty of adaptive meshing in simulations is its incredible versatility. It’s applicable across various fields—from automotive to aerospace, and even in medicine. Picture designing a new airplane wing. Traditional methods would be cumbersome and time-consuming, but adaptive meshing streamlines this. In the medical field, simulating the flow of blood through complex networks of vessels becomes more precise, aiding in the design of new medical devices or surgical techniques. And let’s not forget environmental simulations; adaptive meshing allows us to model climate changes with unprecedented accuracy. The adaptive meshing in simulations provides tailor-fit results, making it an invaluable tool across diverse applications.

Adaptive Meshing: Behind the Scenes

Without getting too technical (because who wants that?), the process of adaptive meshing in simulations is fascinating. Essentially, algorithms analyze the different regions of the mesh during simulation. Areas where changes occur most rapidly and dynamically are assigned finer meshes, making sure every little perturbation is captured. Meanwhile, regions of the model that witness less activity have reduced mesh densities. This intelligent resource allocation enables simulations that are both efficient and capable of yielding high-resolution output. It’s like giving your simulation superpowers!

Transforming Simulation Scenarios

Adaptive meshing in simulations opens up a world of possibilities previously constrained by hardware limitations. Consider a scenario where an architect wants to simulate wind flow around a newly designed skyscraper. Using traditional meshing, capturing the intricacies of turbulent eddies at higher altitudes would require significant computational power—resources that are not always available. But adaptive meshing changes the game. It enables the architect to achieve nuanced simulations efficiently. Similarly, adaptive meshing lets environmental scientists model complex phenomena like ocean currents or air pollution spread with more accuracy and fewer resources. Adaptive meshing in simulations isn’t just a step forward; it’s a leap into a more practical and accessible simulation experience.

Wrapping Up the Adaptive Journey

So there you have it! Adaptive meshing in simulations is a revolutionary approach making detailed simulations more accessible and efficient. Its ability to adjust the mesh on the go ensures that computational resources are used judiciously only where they’re needed the most. This allows for faster, more precise simulations without demanding high-end hardware. Whether you’re a budding engineer or a seasoned researcher, adaptive meshing in simulations could be the key to unlocking your next breakthrough. It’s all about maximizing efficiency and precision—making sure you get the most bang for your simulation buck. Happy simulating, folks!