Hey there, tech enthusiasts and fellow blog readers! Today, we’re diving into the fascinating world of elastomers and how the latest simulation techniques can change the game. Imagine materials that stretch, bend, and flex like no other—elastomers are just that! But understanding their behavior requires a set of advanced tools and tricks. So, buckle up as we explore these groundbreaking techniques that are reshaping industries and opening doors to endless possibilities.

Read Now : Particle Collision Detection Methods

Understanding Advanced Elastomer Simulation

Alright, let’s get cozy and talk about advanced elastomer simulation techniques. These tools are like magic wands for engineers and researchers, allowing them to predict how elastomers will behave under different conditions without getting their hands dirty in the lab. These simulations are essential in industries like automotive, aerospace, and healthcare, where understanding material behavior can save time, money, and yes, even lives!

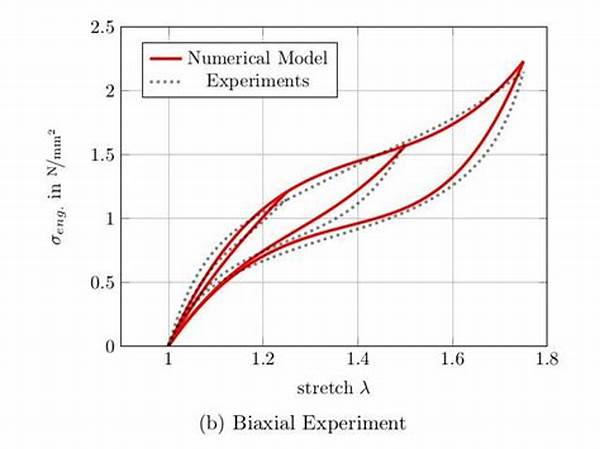

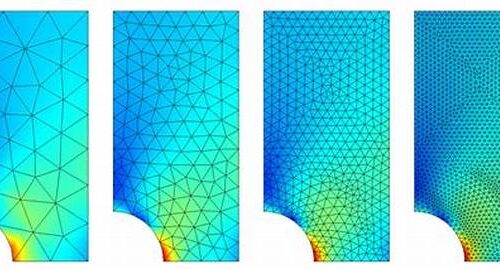

Now, think about it: what if you could predict exactly how a material would perform in the real world without having to build a single prototype? That’s the power of advanced elastomer simulation techniques. With the help of powerful algorithms and computer modeling, engineers can visualize how an elastomer will respond to stresses, strains, and environmental factors. It’s like having a crystal ball for materials science.

In today’s fast-paced world, the ability to quickly iterate design changes and test them virtually is a game-changer. Whether it’s developing new automotive tires or creating innovative medical devices, advanced elastomer simulation techniques are paving the way for safer, more efficient designs. It’s a whirlwind of tech-savvy innovation that’s as exciting as it is revolutionary.

Applications of Advanced Simulation

Elastomer simulations aren’t just for the lab geeks; they’re revolutionizing entire industries! For instance, in the automotive world, advanced elastomer simulation techniques help design durable tires that grip the road like a pro. And in healthcare? These nifty simulations enable the creation of more flexible medical implants. Cool, right?

The aerospace industry isn’t left out, either. Advanced elastomer simulation techniques ensure that components can withstand the extreme conditions of flight and space travel, making them crucial for the safety and reliability of modern aircraft. So, next time you’re flying high, give a little nod to these technologies keeping you safe above the clouds.

And let’s not forget consumer electronics. Your smartphone’s durability might just owe a little something to advanced elastomer simulation techniques. Engineers use these simulations to design cases and components that can withstand daily wear and tear. It’s all about ensuring your gadgets survive the bumps and drops of life.

The Future of Simulation

As technology evolves, so do the tools at our disposal. Advanced elastomer simulation techniques are on a constant path of innovation and refinement. Expect more integration with AI to optimize designs with unprecedented precision! Think faster simulations, fewer errors, and more insights—exciting, isn’t it?

Imagine a future where we can simulate and validate entire production lines virtually before any physical setup occurs. Advanced elastomer simulation techniques could provide the framework for such advancements, ensuring smooth transitions from designs to actual products. This leap forward will undoubtedly cut down on development costs and time significantly.

Moreover, educational platforms and online courses are likely to incorporate these simulation techniques more frequently, with future engineers and designers becoming fluent in using these tools. The next generation could be the most adept at navigating these innovations, pushing boundaries even further into realms we haven’t yet imagined. So, here’s to that thrilling technological horizon brimming with endless possibilities!

Simulation Techniques and Everyday Life

Now, you might be wondering, “How does this all matter to me?” Well, let us break it down for you. Advanced elastomer simulation techniques affect so much more than just big companies—they have a trickle-down effect that reaches everyone. From the sneakers on your feet to the cars on the street, these simulations help make things better, longer-lasting, and safer.

Take, for example, everyday sportswear. Many brands use advanced elastomer simulation techniques to design products that provide optimal comfort and performance. By virtually testing materials and constructions, they deliver running shoes that help you squeeze out that extra mile or sports gear that keeps you feeling light and agile. It’s like adding a little science to your daily routine.

Even in home commodities, think about those reliable rubber gloves or comfy sofas—they’re all products of this incredible simulation process. It’s fascinating how tools once designed for mega-industries have found their way into our daily lives, influencing choices we make about comfort, style, and safety without us even realizing. Now, that’s some serious behind-the-scenes wizardry!

Key Benefits of Advanced Simulations

1. Cost-Effective Development: Advanced elastomer simulation techniques allow for cheaper prototyping processes. Gone are the days of countless physical models; simulations get it right the first time!

2. Time Efficiency: Engineers can now quickly iterate and optimize designs, speeding up the development phase and getting products to market faster.

3. Safety Assurance: These simulations help identify potential issues before they become real-world problems, ensuring products are safer and more reliable.

Read Now : Real-time Collision Management Systems

4. Innovative Flexibility: With the ability to explore numerous design avenues cheaply and efficiently, creativity is unleashed. Say hello to endless design possibilities!

5. Environmental Impact: Reduced waste and resource consumption during product testing contribute to a greener planet.

6. Higher Performance: Products designed using these techniques tend to outperform competitors, thanks to precise and optimized modeling.

7. Customer Satisfaction: Fine-tuning before production ensures a better end product, leading to happier users and increased brand loyalty.

8. Cross-Industry Applications: From automotive to healthcare to electronics, diverse fields benefit from these simulation advancements.

9. Improved Materials: Advanced simulations are paving the way for new and improved elastomer materials, tailoring them to specific applications.

10. Data-Driven Insights: Robust simulations yield a wealth of data, allowing for continuous improvement and informed decision-making.

Real-World Impacts of Simulations

Shifting gears to more tangible benefits, it’s clear that advanced elastomer simulation techniques are lighting up pathways across various sectors. For businesses, this means not just evolving, but thriving! Reduced costs, sustainable practices, and consumer satisfaction are all consequential outcomes of harnessing these powerful tools.

Companies exploring innovative solutions for climate change are particularly benefiting from advanced elastomer simulation techniques. By refining processes and materials, they aim to reduce their carbon footprint while maintaining high product standards. It’s a double win that aligns with both business goals and global environmental imperatives.

Additionally, the consistent improvements in product lifespans thanks to simulations mean less frequent replacements for consumers. Not only does this benefit our wallets, but it also mitigates waste generation. The cleaner, leaner production processes fostered by simulations are reshaping consumer expectations, upping the quality and longevity standards across the board.

Advanced Elastomer Simulation Techniques: A Summary

In summary, advanced elastomer simulation techniques are nothing short of revolutionary. They bridge the gap between imagination and reality, offering an unrivaled troubleshooting toolkit for engineers and designers. Imagine identifying flaws early on, optimizing designs on the fly, and delivering products that are not only better but smarter.

Industries of every ilk are integrating these techniques, bringing about significant leaps in innovation and efficiency. From vehicle safety enhancements to cutting-edge medical devices, this technology is the silent force behind many of today’s groundbreaking advancements. It’s like having a backstage pass to the world of cutting-edge industrial wizardry—who wouldn’t want that?

So, whether you’re an aspiring engineer, a tech enthusiast, or simply a curious mind, keep your eye on advanced elastomer simulation techniques. Their potential is vast, and the ripple effects promise to touch all our lives, improving the technologies, products, and conveniences we often take for granted. Here’s to a future where simulations continue to steer the wheel of progress!