Hey there, fellow tech enthusiasts! Today, we’re diving into the fascinating world of Dynamic Elasticity Simulation Techniques. Don’t worry if that sounds like a mouthful; we’re here to break it down into digestible, engaging bits. Whether you’re an engineering guru or just someone with a passing interest in simulation technologies, this topic has a bit of magic for everyone!

Read Now : User-friendly Design Interface

Understanding Dynamic Elasticity Simulation Techniques

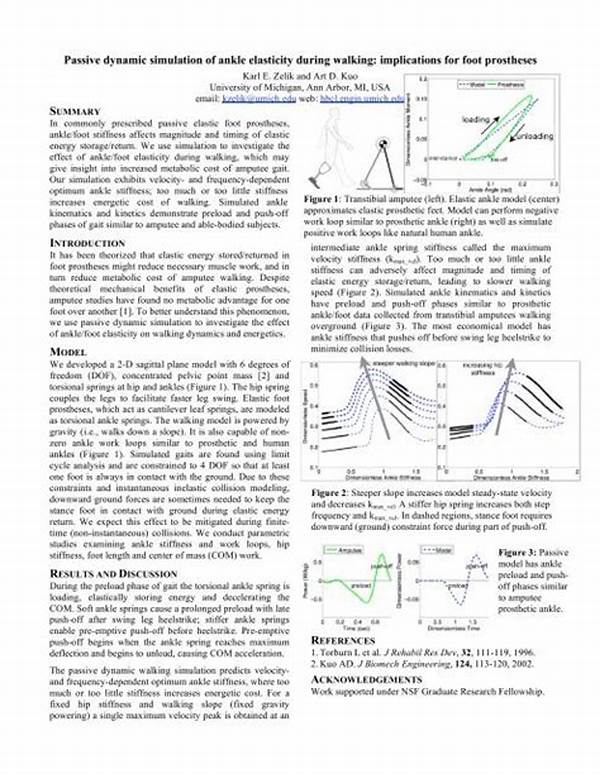

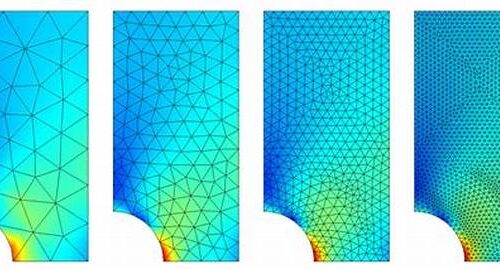

Alright, let’s get into it. Dynamic Elasticity Simulation Techniques are all about studying how materials respond when stress and strain come into play. Think of those cool slow-motion videos where materials bend, twist, or snap back. This is where these techniques shine! Engineers use them to predict how materials behave under various conditions without actually having to stress test real-life prototypes.

The beauty of dynamic elasticity simulation techniques lies in their ability to save time and resources. Imagine testing a product a thousand times in a digital space rather than the physical one, detecting flaws before they become real-world headaches. That’s power and efficiency wrapped up neatly—real nerd-candy for those who love mixing science with creative problem-solving!

The Essence of Dynamic Elasticity Simulation Techniques

1. Speed Meets Accuracy: These simulations provide i-speed responses while maintaining precision. Dynamic elasticity simulation techniques facilitate rapid evaluation.

2. Cost-Effective: Without the need for physical prototypes, dynamic elasticity simulation techniques save money.

3. Predictive Power: These techniques help predict how a material will perform under various conditions.

4. Versatility: From automotive to consumer electronics, dynamic elasticity simulation techniques find purposes everywhere.

5. User-Friendly Interfaces: Thanks to modern graphical tools, engaging with these techniques has never been easier or more intuitive.

Applications of Dynamic Elasticity Simulation Techniques

Dynamic elasticity simulation techniques have found significant applications across a wide array of industries. In the automotive industry, for example, simulations help in designing vehicles that withstand high stress and impact while maintaining safety standards. Engineers can simulate crash scenarios and refine their designs, ensuring improved safety features without multiple costly test phases.

Read Now : “interactive Games Using Visual Tools”

Moreover, in the world of architecture and construction, dynamic elasticity simulation techniques are employed to assess the durability of materials used in buildings and infrastructure projects. This predictive analysis ensures that constructions can endure natural phenomena like earthquakes and strong winds, thereby enhancing public safety. Not only do these simulations guide engineers and architects in material selection, but they also optimize the structural design for longevity and reliability.

Practical Insights on Dynamic Elasticity Simulation Techniques

Dynamic elasticity simulation techniques blend technology with creativity. By simulating various stress tests, engineers can forecast material performance under challenging circumstances without any physical prototypes. This is not just tech wizardry; it’s a game-changer for innovation. Understanding these techniques can provide deeper insights into material behavior and enable more robust design options. Moreover, these techniques challenge us to rethink our approaches to problem-solving, focusing more on virtual testing environments to foster innovation.

Real-World Impact of Dynamic Elasticity Simulation Techniques

The effect of dynamic elasticity simulation techniques on real-world applications is both profound and far-reaching. These technologies reduce the time from concept to market, offering substantial savings and fostering innovation. Companies can rapidly explore new design possibilities without the risk and cost associated with physical trials. By implementing dynamic elasticity simulation techniques, businesses gain a competitive edge, as they can produce more resilient products efficiently. It’s all about smarter, faster, and more reliable outcomes — it’s the future happening right now, folks!

Challenges in Implementing Dynamic Elasticity Simulation Techniques

Nevertheless, like every awesome tool, these techniques come with their set of challenges. The initial setup of dynamic elasticity simulation techniques can be resource-intensive. It requires skilled personnel who understand both the software and the materials science behind the simulations. There’s also the need for continuous updates and recalibrations to ensure simulations remain accurate as new data and materials become available. Despite these challenges, the benefits are undeniable, making it a worthy investment for forward-thinking industries.

Summary and Final Thoughts on Dynamic Elasticity Simulation Techniques

To wrap things up, dynamic elasticity simulation techniques are a pivotal part of today’s engineering and design efforts. By enabling accurate and cost-effective testing, they open up new opportunities for innovation across different sectors. There’s still a lot to explore, and as technology advances, these simulations will undoubtedly become even more integrated into everyday product development processes.

With these techniques, industries aren’t just keeping up; they’re leaping into the future. The next time you marvel at a sleek car or a towering piece of architecture, remember that behind the scenes, dynamic elasticity simulation techniques played a crucial role in bringing those marvels to life. Stay curious and keep exploring—there’s always something new on the horizon!