Hey there, fellow science enthusiast! Today, we’re diving into the fascinating world of materials science, focusing on something you’ve probably never pondered during your morning coffee—grain size and its impact on plastic deformation. Sounds like a fancy cocktail, huh? But trust me, it’s way cooler than it sounds. We’re breaking down this concept in a fun, casual way that you can easily digest, even if you’re not a materials scientist.

Read Now : “animation System With Physics Integration”

Understanding Grain Size in Materials Science

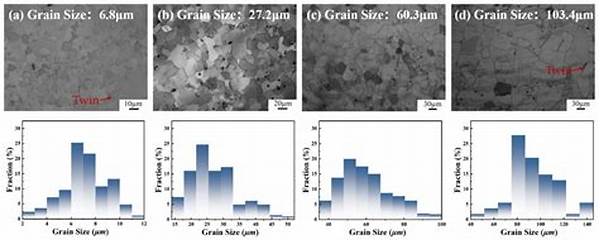

Let’s start by unraveling the mystery of grain size. Imagine metals as a collection of tiny, crystal-like grains stuck together. These grains, much like the individual pieces of a jigsaw puzzle, define how the metal behaves especially when it comes to plastic deformation. Think of plastic deformation as what happens when you bend a paperclip—it changes shape but doesn’t break. Now, here’s where it gets intriguing: the size of these grains can make a world of difference. Larger grain sizes generally increase ductility but might lower strength, while smaller grains pump up the strength but reduce ductility. So, the grain size impact on plastic deformation is a balancing act between strength and flexibility, much like deciding between having that extra slice of pizza or sticking to your diet.

The Science Behind Grain Size

1. Grain Boundaries: These act like the walls in a house, impacting how the deformation moves. The more boundaries, the harder it is for deformation to occur. So, grain size impact on plastic deformation hinges a lot on these boundaries.

2. Strength Vs. Ductility: It’s a classic tug-of-war. Smaller grains generally mean higher strength, but the material becomes less ductile. Grain size impact on plastic deformation is all about finding that sweet spot.

3. Temperature Effects: Heat alters grain size, usually making them grow. As a result, grain size impact on plastic deformation can change with temperature, affecting how a material bends or breaks.

4. Alloy Composition: Different elements can alter grain size. Some alloys are designed to keep grains small, optimizing grain size impact on plastic deformation for specific uses.

5. Manufacturing Processes: Techniques like rolling or annealing happen on a microscopic level, changing grain sizes, and thus the grain size impact on plastic deformation.

Read Now : Top Tutorials For Beginner Game Developers

Grain Size and Everyday Applications

Ever wonder why some materials seem invincible while others easily give up? The answer often lies in the grain size. For instance, car manufacturers might tweak grain sizes to make car frames both strong and flexible enough to withstand impacts. The grain size impact on plastic deformation plays a crucial role in optimizing these materials for safety. Additionally, the electronics you adore, from your smartphone to your laptop, rely on grain size’s influence to ensure components function and last. It turns out, those microscopic grains are pretty mighty!

Why the Industrial World Cares

Industries are constantly on the hunt for that ideal balance between strength and flexibility—and that’s where the grain size impact on plastic deformation enters the chat. Aircraft, bridges, and skyscrapers need materials that won’t give up under pressure while providing the necessary flexibility to avoid fractures. Engineers carefully consider how grain size affects plastic deformation, making it a fundamental aspect of industrial design. The right grain size can add years to a structure’s life, ensuring safety and reliability. It’s almost like choosing the right shoes for trekking—you need the perfect fit to handle the journey successfully.

Delving Deeper: The Micro World

When we zoom into the microscopic level, things get geeky but fascinating. Picture each grain in the metal having its unique orientation and properties. As you apply force, grains start interacting, transferring stress along the boundaries, much like a chain reaction. The grain size impact on plastic deformation is like a complex dance, where each grain plays its part in a grand performance. Smaller grains can block these interactions more effectively, making the material stronger. Yet, too much blocking reduces ductility, making it less bendable. Thus, researchers are like artists, mastering the art of manipulating grain size to get just the right performance from materials.

Summary: The Unseen Forces at Play

To wrap it up, the grain size impact on plastic deformation is an unseen force that dramatically influences material performance. It determines whether something bends or breaks, withstands pressures or fails. Whether it’s creating super-strong alloys for aircraft or designing everyday gadget casings, the role of grain size cannot be understated. Next time you bend a paperclip or watch a skyscraper sway in the breeze, remember the incredible science beneath the surface. Grain size may be tiny, but its impact is colossal—shaping our modern world one microscopic grain at a time. Who knew something so small could have such a big impact?