Hey there, fellow tech enthusiasts! Today we’re diving into the fascinating world of laser triangulation scanning methods. If you’re like me, you probably find yourself blown away by the complexity and precision of this technology. But don’t worry, I’m here to break it down with a casual chat. So grab your cup of coffee (or tea, if that’s your thing), and let’s get into it.

Read Now : Reducing Computational Costs In Collision Detection

What are Laser Triangulation Scanning Methods?

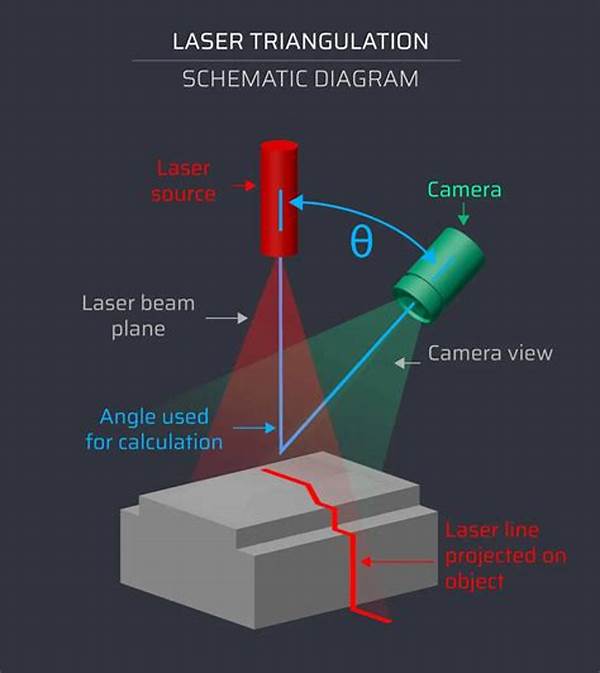

Alright, let’s tackle what laser triangulation scanning methods are all about. Picture this: you’re using a non-contact technique to measure an object’s surface, gathering precise data points along the way. Sounds cool, right? This method is all about bouncing a laser beam off a surface and capturing the reflected light with a camera. The data collected is then used to determine distances based on the angles and time taken for the laser to return—like high-tech magic, only it’s all grounded in science.

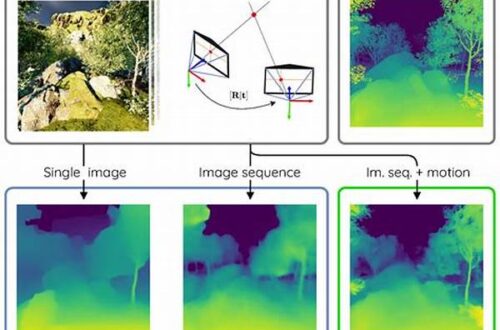

Now, why does this matter? Well, laser triangulation scanning methods are used in various industries—from manufacturing to healthcare. These methods help create incredibly detailed 3D models, possibly even ones you might see in futuristic movies. Imagine creating a digital twin of an object without laying a finger on it. Pretty neat, huh?

What sets laser triangulation scanning methods apart is their sheer precision. We’re talking fractions of a millimeter in accuracy, folks. So, when unsure about how a piece fits into the puzzle, this technology comes to the rescue by ensuring everything adds up perfectly. Thanks to its efficiency, it makes processes faster, cheaper, and less prone to errors.

How Does Laser Triangulation Work?

1. The Setup: It all starts with a laser, a camera, and a target object. Arrange them in a triangular setup, and you’re good to go!

2. Beam Bouncing: When the laser hits the object, it reflects back to the camera, forming a unique angle.

3. Data Collection: The camera collects the reflected light data, determining the exact distance from the laser source to the object’s surface.

4. Data Processing: The collected data is processed to create precise 3D models, showing every nook and cranny of the object.

5. Accuracy: Laser triangulation scanning methods are lauded for their high precision, capable of capturing minute details that other methods might miss.

Applications in Modern Industries

Dive into the applications, and you’ll find laser triangulation scanning methods are practically indispensable in diverse fields. In manufacturing, they’re key in quality control, ensuring components are made to exact specifications. This tech helps maintain high standards, ensuring everything runs like a well-oiled machine. Car makers, for example, use it to check that vehicle parts fit perfectly without the risk of defects due to human error.

Read Now : Game Creation For Visual Artists

In healthcare, these scanning methods help create detailed scans of body parts, aiding in the design of prosthetics or even performing advanced diagnostics. The precision offered by laser triangulation scanning methods means medical professionals can identify issues with incredible accuracy. So, it’s not just about creating cool gadgets but also saving lives and improving healthcare outcomes.

Let’s not forget about the world of entertainment—where these methods are used in creating realistic animations and special effects, ensuring viewers become fully immersed in fictional universes. By adding to the realism and detail, these scanning techniques contribute significantly to the movie magic we all love. All these applications truly highlight the versatility and importance of laser triangulation scanning methods in our world today.

Challenges and Future of Laser Triangulation

Sure, laser triangulation scanning methods sound like the perfect tech solution, but like any technology, they come with a few challenges. For starters, highly reflective or transparent surfaces can distort data collection. It’s like trying to take a mirror selfie with too much sunlight glaring into the camera—not ideal, right? These quirks mean that certain adjustments or additional coatings may be required to gather accurate data.

Despite these hurdles, the future of laser triangulation scanning methods looks undeniably promising. With ongoing advancements in laser technology and computational processing, there’s potential for greater breakthroughs. Imagine even more robust systems able to tackle complex scanning scenarios with ease. The day may not be far off when these methods become even more ubiquitous in daily life, continually pushing boundaries of what’s possible.

Wrapping it Up

To sum it all up, laser triangulation scanning methods aren’t just a technical marvel—they’re also a workhorse in today’s technological landscape. From ensuring your car parts fit snugly to helping doctors provide better patient care, these methods are undeniably woven into the fabric of modern life. They not only offer high precision but also help industries innovate and enhance product quality.

Despite some limitations, the future shines bright for laser triangulation scanning methods. We can expect them to continue evolving, overcoming challenges, and expanding their reach across various fields. As technology keeps advancing, there’s little doubt these methods will remain at the forefront of innovation. They’re not just about precision but also about improving our world in ways we might not even fully appreciate yet.

Thanks for sticking with me through this deep dive into laser triangulation scanning methods. I hope you’ve found our casual chat both refreshing and enlightening. So, the next time you admire some cutting-edge technology, take a moment to appreciate the small yet significant role that laser triangulation might have played in bringing it to life!