Ever wondered how engineers and scientists manage to predict the behavior of elastic materials under various conditions? Well, buckle up because today we’re diving into the world of numerical methods for elastic materials. This topic might sound a bit geeky, but trust me, it’s fascinating stuff. Whether you’re a seasoned professional or just a curious mind, there’s something here for everyone. Let’s break this topic down, shall we?

Read Now : Advanced Scripting In Game Engines

The Basics of Numerical Methods for Elastic Materials

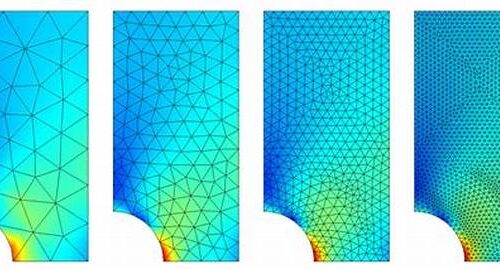

Understanding numerical methods for elastic materials is like unlocking a mystery of how objects stretch, bend, and bounce back. At the core, these methods are all about using mathematical models to simulate the behavior of materials that return to their original shape after being deformed. Imagine pulling on a piece of rubber and then watching it snap back. That’s elasticity in action, and numerical methods allow us to predict this behavior without intense physical testing.

These methods involve complex calculations, often utilizing computers to solve equations that describe elasticity. Engineers and scientists use software that applies algorithms to model elastic behavior under different loads and conditions. By using these simulations, they can forecast how materials will perform in real-world situations, helping to design everything from bridges to sports equipment.

In simpler terms, numerical methods for elastic materials provide a virtual playground for experimenting with materials. Instead of building multiple prototypes, you can test different scenarios on a computer model. This not only saves time and resources but also opens up endless possibilities for innovation. You’re basically blending mathematics, physics, and computer science to revolutionize material design and engineering.

Applications of Numerical Methods for Elastic Materials

1. Product Design: Using numerical methods for elastic materials helps in fine-tuning product designs effectively, ensuring they perform well under stress.

2. Research and Development: Researchers apply these methods to explore new material properties by testing various hypothetical scenarios.

3. Automotive Industry: Testing crash scenarios through simulations, to keep passengers safe, wouldn’t be possible without numerical methods for elastic materials.

4. Civil Engineering: Before laying down a single brick, engineers use these methods to predict how structures will behave under loads.

5. Medical Devices: Prosthetics and orthotics benefit immensely from these methods, as the materials used need precise elasticity for comfort and efficacy.

Challenges in Numerical Methods for Elastic Materials

Okay, so numerical methods for elastic materials sound pretty awesome, right? But like any other cool tech, they come with their own set of challenges. First off, one of the most significant hurdles is getting precise input data. The accuracy of your predictions is only as good as the data fed into the system. Garbage in, garbage out, as they say!

Another issue is computational power. Simulating material behavior, especially in complex structures, can be a resource-heavy task. It requires high-performance computing capabilities, which can be costly. And let’s not forget the learning curve. These methods are intricate, and mastering the software and understanding the mathematics involved takes time and expertise.

Despite these challenges, the field is continuously advancing. With the development of more robust algorithms and the increase in computational power, numerical methods for elastic materials are becoming more accessible and easier to implement across various industries.

Importance of Numerical Methods for Elastic Materials

The field of numerical methods for elastic materials is more indispensable than you might think. First, these methods save time. Building and testing physical prototypes can be a lengthy endeavor. Simulations can drastically cut down on this time, getting products to market faster. Plus, let’s not ignore the cost factor; fewer physical models mean less money spent.

Risk reduction is another significant benefit. By predicting how materials will react under extreme conditions, we can prevent potential failures before they even happen. This proactive approach is essential, especially in industries where safety is paramount, like aerospace or automotive.

Finally, innovation thrives on numerical methods. They allow engineers and scientists to push the boundaries of what materials can do. Exploring new compounds and designs becomes more straightforward when you can simulate outcomes before pursuing real-world testing. The contribution of these methods to technological and scientific advancements is genuinely remarkable.

Future of Numerical Methods for Elastic Materials

Looking to the future, the potential of numerical methods for elastic materials is truly exciting. As computing power continues to grow, simulations are becoming more accurate and faster, allowing for more complex analyses in shorter periods. This progress means we’ll see even more innovation in how materials are used and understood.

AI and machine learning are also starting to play a role, offering new ways to optimize simulations and predict material behavior. These technologies can find patterns and insights that traditional methods might miss, making predictions more robust and trustworthy. Imagine a world where machines automatically recommend material choices based on previous data and analyses.

Read Now : Analyzing Event Sheet Structure

Moreover, as sustainability becomes a global focus, these methods are crucial in developing eco-friendly materials. By predicting how sustainable materials will behave, industries can move towards greener manufacturing processes. The numerical methods for elastic materials are not just about efficiency and innovation but also about making a positive impact on the planet.

Advantages of Numerical Methods for Elastic Materials

1. Efficiency: Numerical methods for elastic materials streamline testing and development processes, making them more efficient.

2. Cost-Effective: Reducing the need for physical prototypes saves money and resources.

3. Risk Management: Anticipating failure points can prevent disasters, especially in safety-critical industries.

4. Innovation: Encourages exploration of new materials and engineering approaches.

5. Sustainability: Helps in creating and testing environmentally friendly materials.

6. Customizability: Simulations can be tailored to specific needs and conditions.

7. Accuracy: Advanced algorithms ensure precise and reliable predictions.

8. Versatility: Applicable across multiple industries, enhancing product development.

9. Scalability: Easily adapts to projects of various sizes and complexities.

10. Global Impact: Contributes to advancements in technology and scientific research worldwide.

Final Thoughts on Numerical Methods for Elastic Materials

As we wrap up our foray into numerical methods for elastic materials, it’s clear that this field is more than just an academic endeavor. It’s a practical, often essential tool in modern engineering and design. By offering insights and solutions that are both innovative and efficient, these methods are set to continue shaping the future of materials science in profound ways.

While challenges exist, the ongoing advancements in computational power and algorithm development promise a bright future. We’re only beginning to scratch the surface of what’s possible. From making our world safer to driving innovation and sustainability, numerical methods for elastic materials are at the forefront of modern industrial evolution.

So next time you see a new building springing up, or a groundbreaking gadget release, remember—the quiet influence of numerical methods is probably at play, ensuring that these products are the best they can be. Whether you’re in the field or an interested bystander, there’s no denying the power and potential of these incredible tools.