Hey there, fellow tech enthusiasts! Today, let’s dive into the fascinating world of surface profilometry measurement methods. Okay, maybe it doesn’t sound like the flashiest topic at first, but trust me, it’s a crucial tool across various industries. Whether it’s ensuring the smoothness of a smartphone screen or checking the texture of a luxury car, this stuff matters! So, grab your coffee and settle in for a casual chat on how these measurement methods make the world go round!

Read Now : Visual Scripting Game Creation Tool

The Basics of Surface Profilometry Measurement Methods

Alright, let’s break it down. Surface profilometry measurement methods are basically tools and techniques used to measure the roughness, smoothness, and texture of a surface. Think of them as the rulers and microscopes for engineers and quality inspectors. They help us ensure that surfaces meet their desired specifications, which is critical whether you’re manufacturing a space shuttle or crafting jewelry. Most methods involve creating a 3D map of the surface, which then allows experts to analyze all the tiny peaks and valleys. Fancy, right?

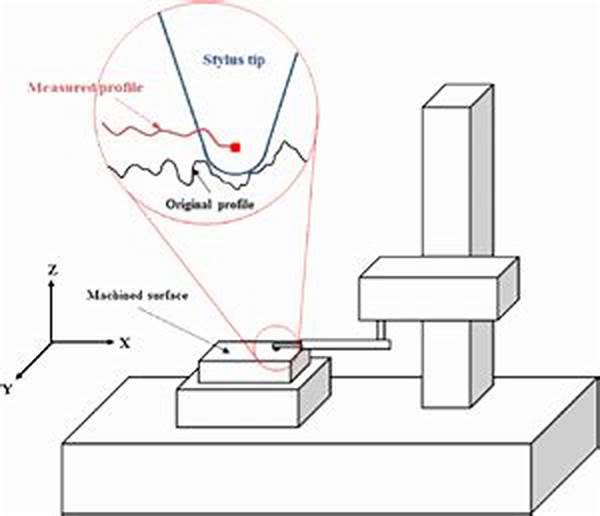

Now, what makes surface profilometry measurement methods so cool is their diversity. There are contact methods, like stylus profilometers where a little needle traces over the surface. Then, there’s the no-touch crowd like laser scanning confocal microscopy, which uses light to do the heavy lifting. Each method has its strengths and fits different scenarios. It’s like choosing the right tool from a Swiss Army knife based on what you need to get done. Some are perfect for super fine details, while others handle larger surface areas. So, picking the right one involves knowing your material and what exactly you’re looking to measure.

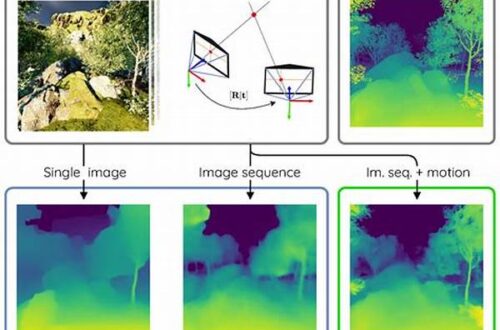

And lest we forget, technology has catapulted these measurement methods into the future. With advances in software, now we can visualize and manipulate complex surface data with ease. Imagine looking at a 3D hologram of your surface right on your computer screen. This makes it easier for engineers and designers to tweak designs and make informed decisions. As industries become more tech-savvy, surface profilometry measurement methods will only continue to evolve, and we’ll continue to marvel at their ingenuity.

Understanding Key Surface Profilometry Methods

Let’s delve into some key methods! Stylus Profilometry involves a tiny needle sliding over the surface, capturing details with precision. Laser Scanning Confocal Microscopy is all about using lasers to map out those microscopic surface features. These surface profilometry measurement methods offer accuracy and cater to diverse needs across various industries.

White Light Interferometry utilizes light waves to measure the surface profile, ideal for smooth and reflective surfaces. Atomic Force Microscopy employs a cantilever to ‘feel’ the surface, providing atomic-level detail. Lastly, Focus Variation excels in measuring steep surfaces and sharp edges through focusing techniques. These surface profilometry measurement methods are truly diverse tools.

Choosing the Right Surface Profilometry Method

So you’re ready to choose a method? Great! Each surface profilometry measurement method shines in different situations. For delicate surfaces, non-contact methods like laser-based profilometry prevent damage. They’re perfect for items like delicate electronics or artworks. Meanwhile, the contact methods are your champs when dealing with rough, durable surfaces.

However, it’s not just about the material. Consider the level of detail you need. Need to go atomic? That’s where atomic force microscopy comes in. If you’re focusing on broader surface areas, stylus or laser techniques might be more up your alley. Another factor? Speed! Some methods are quicker but may trade off fine details, while others require time but reward you with incredible insights.

In the end, it’s about balance. Weigh your priorities like the delicacy of your material, the precision required, and the time you have. With so many fantastic surface profilometry measurement methods to choose from, you’ll find one that fits like a glove. Whether you’re innovating in tech, med-tech, manufacturing, or something uniquely different, there’s a profilometry method designed just for you.

Top Applications of Surface Profilometry Methods

It’s time to get into why these methodologies matter! First up, electronics. Surface profilometry measurement methods ensure that components like semiconductors are flawless. After all, we all love our smartphones chip-full-free! Then there’s aerospace. Smooth surfaces are crucial for aerodynamics and overall safety, and profilometry ensures every inch is immaculate and flight-ready.

In automotive, these methods help maintain consistent surface finishes on vehicles, ensuring both aesthetics and functionality. The medical field benefits as well. Surface profilometry measurement methods inspect the micro-texture of implants, ensuring they interact well within the human body. In materials science, various surfaces undergo trials, and profilometry provides insights into how surfaces withstand stress, chemical reactions, and more.

Manufacturing? Big yes! Profilometry verifies product specifications, reducing waste and saving time. Even art conservation relies on surface profiling to map and understand ancient murals and paintings without damaging them. Ultimately, these methods play an instrumental role across industries, proving their importance in modern technology and restoring historical artifacts alike.

Read Now : Precise Hitbox Boundary Calculations

Practical Aspects of Surface Profilometry in Industry

Now let’s talk about how the industry uses these fancy gadgets! In the real world, surface profilometry measurement methods are like the unsung heroes. Picture this—manufacturing facilities where every step of the production utilizes these techniques to check quality. They’re the safety net ensuring no defective products pass through, preserving brand quality and customer trust alike.

In quality control, a surface’s texture can influence functionality. For instance, the roughness of brake pads affects their grip. Profilometry answers these burning questions, making sure everything works like a charm. They’re critical in ensuring parts fit together perfectly, from car engines to the tiny gears in a watch. A tiny flaw on a surface? Could spell disaster! Profilometry keeps such catastrophes at bay.

Plus, as we get more advanced, it’s all about sustainability! Surface profilometry measurement methods contribute to waste reduction by ensuring optimal use of materials. What’s more rewarding than knowing you’re conserving resources while maintaining exceptional quality? So next time you see a flawless gadget or drive a notably smooth vehicle, give a little nod to these behind-the-scenes magicians.

Challenges and Troubleshooting in Surface Profilometry

But wait, it’s not all rainbows! Using surface profilometry measurement methods has its share of hurdles. Calibration is critical; a poorly calibrated device could lead to inaccurate measurements. Imagine the entire manufacturing process halting due to erroneous data—yikes! It’s vital to ensure precision right from the beginning to avoid costly errors down the line.

Another challenge is dealing with diverse surface types. Reflective or transparent surfaces can be tricky as they may distort readings. Knowing your material and selecting the appropriate method are crucial steps. Additionally, high-frequency ambient vibrations in the testing environment can interfere with measurements. Isolating your setup or conducting tests in controlled conditions often becomes necessary.

Moreover, data interpretation requires a trained eye. Complex surfaces can result in massive amounts of data that require efficient algorithms and analytical know-how to decipher. Even with advanced software, the right expertise is a must for accurate analysis. Remember, while the gear is increasingly high-tech, human skill remains priceless in interpreting results accurately.

Summary of Surface Profilometry Measurement Methods

So, what’s the final verdict on surface profilometry measurement methods? These methods are indispensable in ensuring products meet rigorous quality standards. With diverse applications across electronics, automotive, aerospace, and more, they are highly versatile tools in modern manufacturing and design. They cater to a plethora of industries, offering tailored solutions for unique needs and materials.

From enhancing smartphone surfaces to verifying the strength of new materials, these methods are integral to technology advancement. Surface profilometry measurement methods provide the data needed to innovate and create, becoming the guardians of quality control. Despite challenges like calibration and data interpretation, their benefits immensely outweigh the drawbacks.

In the fast-evolving technological landscape, these methods continue to evolve. The future promises even more precise measurements, integrating AI for smarter and swifter process implementations. So here’s to surface profilometry measurement methods—steady, reliable, and a true marvel of the modern world!