Hey there, fellow enthusiasts of everything technical! Today, we’re diving into a topic that’s as exciting as it sounds — “user-defined material parameters.” Whether you’re a seasoned engineer, a budding scientist, or just a curious mind, this concept is bound to tickle your brains. Imagine having the power to define the characteristics of the materials you’re working with. Sounds cool, right? Well, it’s not just a wild science-fiction dream anymore. So, grab your metaphorical pens, and let’s take a peek into this fascinating world!

Read Now : Game Loop Performance Enhancement Strategies

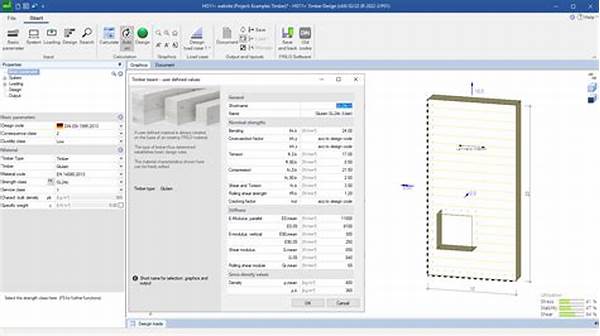

Understanding User-Defined Material Parameters

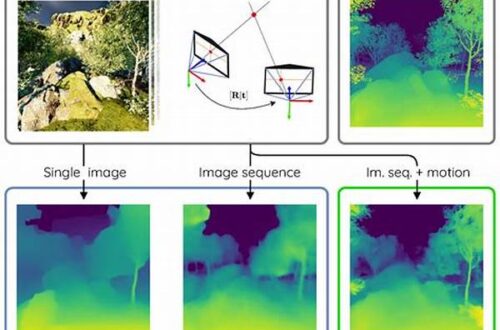

User-defined material parameters are a game changer in the world of engineering and simulations. Gone are the days of being stuck with pre-set material attributes! These parameters allow you, yes you, to tweak and perfect material characteristics as per your needs. Imagine being able to customize and simulate materials without having to conform to conventional limits! Before, if you wanted to ensure a certain strength or flexibility, you’d have to make do with what was available. But now, it’s all in your hands. You can input, adjust, and manipulate data to understand how materials behave under varying conditions. This flexibility not only saves time but also opens a door to innovation, enabling us to push boundaries like never before. With user-defined material parameters, you’re essentially the master of materials, juggling various factors to get the desired result. It’s like playing with the ultimate toolbox where the boundaries are defined by your imagination (and maybe a bit of physics too).

The Benefits of User-Defined Material Parameters

1. Customization Heaven – With user-defined material parameters, customization in material properties is as easy as pie. You get to create, modify, and define precisely how you want your materials to behave. It’s like having a tailored suit but for your engineering needs.

2. Enhanced Precision – Whether it’s a complex simulation or a basic parameter adjustment, user-defined material parameters offer an unmatched level of detail. You get to set specific values that ensure your outcomes are more accurate and credible.

3. Flexibility and Adaptability – In a world where things change rapidly, having materials that can adapt is crucial. These parameters allow you to simulate potential scenarios and ensure your materials stand the test of time and conditions.

4. Cost-Efficiency – Forget lengthy trial and error or expensive prototypes. By using user-defined material parameters, you can simulate and rectify potential issues beforehand, saving valuable resources and time.

5. Innovation Booster – This technology not only enhances current processes but also pushes for innovative techniques and solutions. You’re no longer limited to traditional methods but encouraged to explore beyond conventional boundaries.

Exploring the World with User-Defined Material Parameters

There’s a whole world out there just waiting to be explored, especially when you have user-defined material parameters at your disposal. Picture yourself at the helm of a spaceship, journeying through the vast expanse of possibilities. With these parameters, you’re not just addressing current needs but pioneering the future of material science. Let your imagination run wild as you customize and simulate all kinds of materials for any application you can think of. Think of it like having a paintbrush in a world of plain canvases, where you’re free to make your colorful mark. Whether it’s testing new materials for building a more sustainable future or speeding up the development of the next technological innovation, the freedom and adaptability of these parameters are indispensable. So, pop on your explorer’s hat and dive into the limitless ocean of potential that user-defined material parameters hold.

Practical Applications of User-Defined Material Parameters

User-defined material parameters find their applications in countless fields:

1. Aerospace Engineering – Tailoring material features that withstand extreme speeds and pressures is crucial, and these parameters make it easier than ever.

2. Automotive Design – From crash simulations to aerodynamics testing, modifiable parameters allow for a safer and more efficient vehicle design.

3. Biomedical Engineering – Crafting materials suited for implants or devices tailored to individual physiological properties has become a reality.

Read Now : Cost-effective Game Development Solutions

4. Civil Engineering – Ensuring materials meet unique environmental and structural requirements is facilitated by precise parameter modifiers.

5. Consumer Electronics – With rapid changes in technology, the ability to redefine materials for newer devices is essential.

6. Sustainable Energy – Designing materials for solar panels or wind turbines that use user-defined parameters enhances efficiency and sustainability.

7. Textile Industry – Create fabrics with specific qualities like water resistance or breathability using adjustable parameters.

8. Nanotechnology – Explore the science of the exceedingly small by defining parameters for nanomaterials, paving the way for advanced innovations.

9. Sports Equipment – From customizing weight to aerodynamics, athletic gear can be fine-tuned to improve performance using these defined parameters.

10. Architecture and Design – Designers can now experiment with materials that offer unique aesthetics while retaining necessary structural integrity.

Future of Innovation with User-Defined Material Parameters

The future shines brightly with the potential user-defined material parameters bring. As we forge ahead, the role of these flexible parameters is only going to grow in importance. Imagine a future where every product, every material, is optimized to perfection for its specific use—all thanks to these dynamic parameters. The innovation potential is exponential, accelerating developments in fields we hadn’t even considered. Just think of research labs where scientists craft new materials overnight, or industries solving age-old problems with fresh, innovative solutions made possible by user-defined material parameters. The path ahead is lined with endless possibilities and an open road for creativity. It’s a thrilling prospect to consider how this technology can transform the world as we know it—a realm where definitions are constantly evolving, pushing humanity toward greater accomplishments. So, if there’s ever been a time to embrace a forward-thinking mindset and let curiosity lead the way, it’s now.

Final Thoughts on User-Defined Material Parameters

So, what’s the takeaway here? Well, besides the obvious cool factor of shaping materials at will, user-defined material parameters open doors like never before. They’re the tools of modern alchemy, where precision meets creativity. As you go about encountering various bewildering scenarios, remember that this adaptive tool is your secret ally. Imagine living in an age where material limitations are a thing of the past—where your only constraint is how far you’re willing to push your creative edge. With user-defined material parameters, that’s not just a dream, but an accessible reality. Let this newfound freedom of control inspire you—who knows what incredible innovation you might unleash? Whether you’re a tech geek or just someone who loves exploring the limits, this domain promises an exciting journey. Gear up, stay curious, and let’s venture into the endless possibilities together!